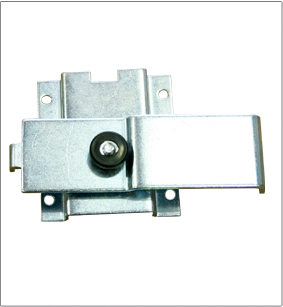

Stage units are equipped with integral couplings that may be selectively engaged as needed to join platforms of the same height or platforms that are 8" different in height. This allows for quick and easy arrangement and rearrangement.

Our Risers are built with a 3/4" plywood core and then wrapped with a steel frame for the ultimate in durability. Spring-bolt brace mechanisms ensure that these risers will stand up to years of constant use and handling.

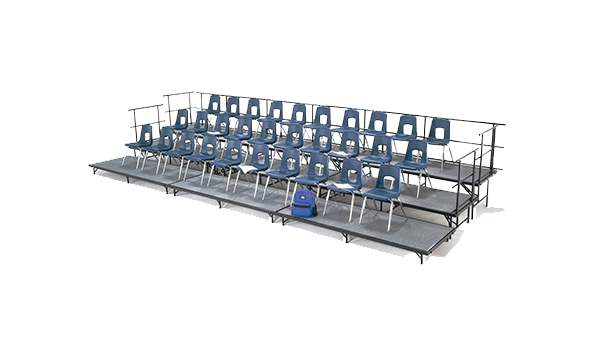

TransFold portable stages give you the freedom to configure the stage to create any performance environment you can imagine. Our convenient modules give you the flexibility to build the exact size and shape stage that you need to accommodate your event. With TransFold, you are the director.

SAFETY NOTICE: Guard rails should be used on sides and rear.